PRODUCTS/BUTT FUSION MACHINES

Hydraulic Butt Fusion Machine V1000 630MM-1000MM (24” IPS – 42” IPS) | For Plastic Pipe Welding

The hydraulically operated butt fusion machine is featured by robust, compact and rugged reliability. The hydraulic power station gives sufficient pressure to butt fusing pipes and fittings with a variety of pressure ratings. And Riyang hydraulic butt fusion machine is compatible with Riyang data logger, which records and documents the key parameters of the fusion process.

Hydraulic Butt Fusion Machine V1000 630MM-1000MM (24” IPS – 42” IPS) | For Plastic Pipe Welding

V1000 is an on-site hydraulic plastic pipe welding machine suitable for welding plastic pipes and fittings made of HDPE, PP, PVDF, and other thermoplastics materials.

Product Details

WELDING RANGE O.D. 630MM – 1000MM

PISTON AREA 38.8 CM

POWER SUPPLY 380V±10%, 50/60HZ

TEMPERATURE RANGE MAX. 320ºC

HEATER POWER 17.5KW

PACKING DIMENSION 2550*1850*1800 MM, 1600*1150*1900 MM, 800*350*400 MM

TRIMMER POWER 3.0KW

PUMP POWER 2.2KW

WORKING PRESSURE RANGE 0 – 140 BAR

GROSS WEIGHT 2318KGS

Basic Frame

Featured by

Oil seal kit, origins from Germany, make sure that the pressure performance stays in a more stable way.

Heating Plate

Featured by

We use Dupont from the USA for coating the heating plate, which is the best in the industry. It’s many stickers on an aluminum plate, more non-sticky to plastic pipes surface. The temperature deviation of different points on the heating plate is 2-3 degrees (small size machine) and 5-6 degrees (big size machine).

Trimmer

Featured by

Support

Featured by

Ergonomic design

Electrical box Assy

Featured by

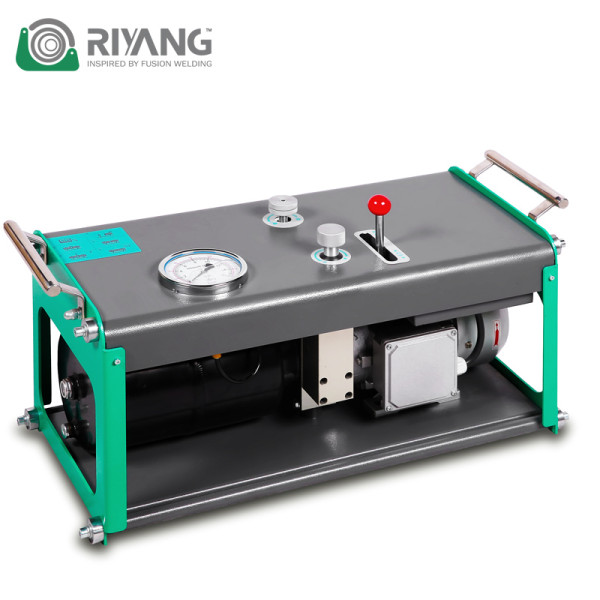

Hydraulic Power Station

Featured by

Solid relays have a bigger load capacity and working in a more stable situation, which has a much longer life.